Unveiling the Future of Manufacturing: The Dummy Bar Revolution

2024-05-17 15:31In the ever-evolving landscape of manufacturing, innovation stands as the cornerstone of progress. Among the latest advancements poised to reshape the industry is the advent of the "Dummy Bar" technology. This groundbreaking development promises to streamline processes, enhance efficiency, and revolutionize the way steel is produced.

What is a Dummy Bar?

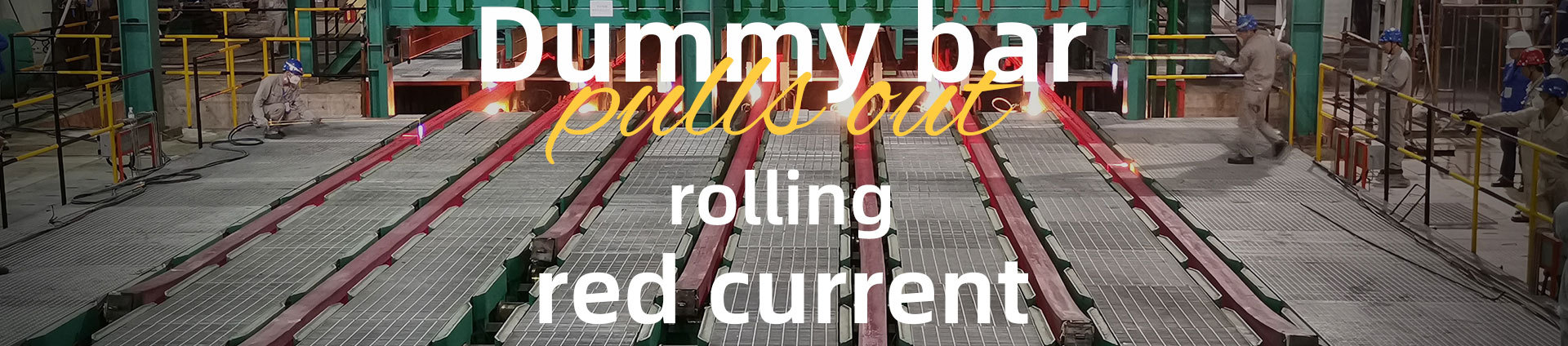

A dummy bar is a critical component in continuous casting, a method widely used in the steelmaking process. Traditionally, during a casting sequence, molten steel would solidify in the mold, necessitating a pause in production to remove the solidified steel and reinsert a new mold. This interruption not only leads to downtime but also poses safety risks and hampers productivity.

The introduction of the dummy bar eliminates this need for interruptions. Essentially, it is a temporary "stand-in" that replaces the solidified steel, allowing the continuous casting process to proceed seamlessly without interruptions.

*Advantages of Dummy Bar Technology:*

1. **Enhanced Efficiency:** By enabling continuous casting without interruptions, dummy bar technology significantly boosts efficiency in steel production. The continuous flow minimizes downtime, leading to increased throughput and reduced operational costs.

2. **Improved Safety:** Traditional methods involving mold changes pose inherent safety risks associated with manual handling of heavy equipment and exposure to high temperatures. Dummy bar technology mitigates these risks by automating the process, thereby ensuring a safer working environment for operators.

3. **Cost Savings:** With increased productivity and reduced downtime, manufacturers can achieve substantial cost savings over time. Additionally, the streamlined process requires fewer resources, further contributing to overall cost efficiency.

*Industry Impact:*

The adoption of dummy bar technology is poised to have a profound impact across the manufacturing sector. Steel producers, in particular, stand to benefit significantly from the increased efficiency and cost savings afforded by this innovation. Furthermore, the ripple effects extend to downstream industries reliant on steel products, potentially leading to improved supply chain dynamics and enhanced competitiveness.

*Future Prospects:*

As technology continues to advance, the evolution of dummy bar technology is likely to continue. Innovations such as intelligent sensors, predictive analytics, and automation are expected to further optimize the casting process, driving even greater efficiency and productivity gains.

*Conclusion:*

The emergence of dummy bar technology represents a paradigm shift in the manufacturing landscape, particularly in the steel industry. By enabling continuous casting without interruptions, this innovation promises to enhance efficiency, improve safety, and deliver significant cost savings. As manufacturers increasingly embrace this transformative technology, the future of steel production looks brighter than ever before.

In a world where progress is measured by innovation, the dummy bar stands as a testament to the relentless pursuit of excellence in manufacturing.