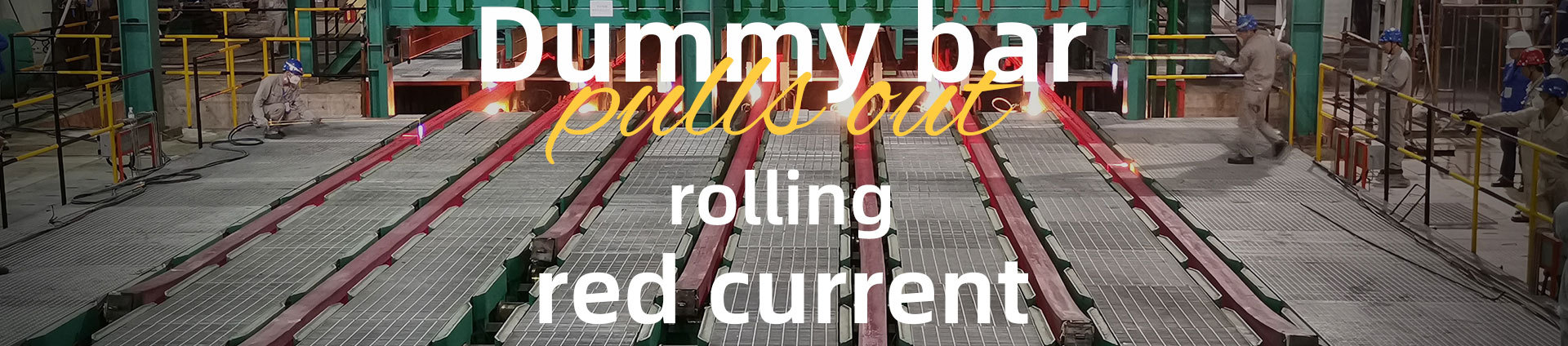

Manufacturing process and quality control of dummy bar

2023-06-21 09:06In order to better ensure the processing quality and service life of the chain dummy bar in the working environment of the steel plant, our factory has the following technical process requirements:

1. Requirements for raw material

The material should meet the customer's drawing requirements, choose a large brand and manufacturer forging factory, ensure smooth material procurement channels, accurate materials, and provide a material list.

2. Check the heat treatment process

The selected heat treatment manufacturer should have electric furnaces and other heat treatment equipment with various sizes of components. Having good testing methods and quality tracking testing plans. We have rich production experience in the quenching and tempering treatment and surface quenching of materials such as 42CrMo.

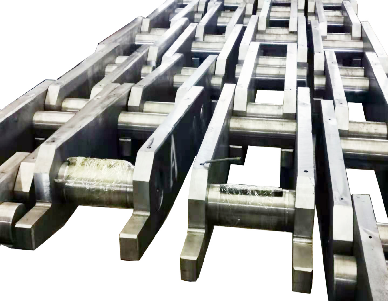

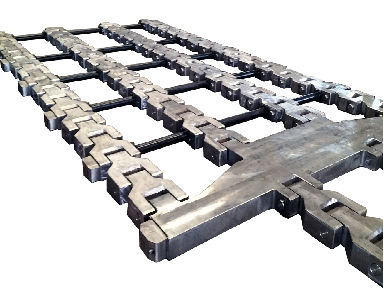

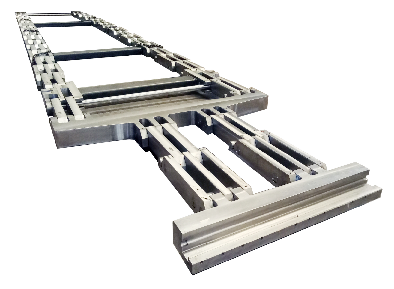

3.Strict control of machining accuracy in mechanical processing

Strictly control the fit tolerance, positional tolerance, and surface finish of the shaft and hole during processing. Dimensional tolerances that cannot be guaranteed on ordinary machine tools must be completed on CNC lathes and machining centers. Strictly control the size of the deflection and side bending according to the drawings.

4. Strict inspection and tracking assembly

When the dummy bar meets the assembly conditions, first check whether the quenching and tempering and surface hardening hardness meet the drawing requirements. Spot check each component, match the assembly parts according to the size tolerance number, and assemble them in sections on a dedicated testing device to detect side bending and downward bending. Control the downward bending at 1% and side bending at 1 ‰ in 5 meters. After assembly,, measure the side bending and downward deflection again, with a downward deflection of no more than 1.5% and a side bending of no more than 1 ‰.

5. Factory requirements

Before leaving the factory, all relevant departments have strict control over the products, and they can only leave the factory after passing the inspection and being signed by the relevant responsible person.